For the "sliding vane" type blower..

Eg Judson, Wray, Cozette Shorrock, Centric etc

Remove one end of the blower to expose the rotor, bore and vanes. Do a pencil

or finger rubbing of the chamber area between the first 2 vanes as red marked

above.

I use cm graph paper so it is easier and more accurate to work out the area.

Make sure one vane has just closed off the inlet port.

This red area between the vanes (in sq cm) muliplied by the length of the rotor (in cm) and then multiplied by 6 (in this case as there are 6 chambers per revolution..some blowers only have 4) will give us the total swept volume or capacity of this blower. ie the amount of cc’s it produces per rev.

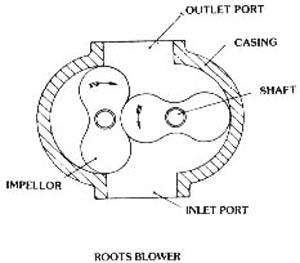

For the "Rootes" type Blower..

Eg Rootes, Marshall, Nordec, McCulloch, the newer modern Japanese type etc

Remove one end of the blower to expose the rotors and bore. Do a pencil or

finger rubbing of the ends of the rotors.

I use cm graph paper so it is easier and more accurate to work out the area.

This area of the rotor ends (in sq cm) muliplied by the length of the rotor (in cm) will give us the total swept volume or capacity of this blower. ie the amount of cc’s it produces per rev. (by displacement..not "sweeping" it)

The Rootes type blower is not "swept volume" type but is actually a "gear" pump or "displacement " pump. Hence the different method of calculating its capacity.

NOTES

Note that in the formula you need to use ½ the capacity of the engine. This

is because a

4 stroke 4 cyl motor only uses two cylinders on firing stroke per revolution

ie there are only 2 cylinders of suction per rev.

With worn blowers particularly the sliding vane type which has the trunnions to prevent the vanes from contacting the bore wall eg Shorrock, Centric, Cozette etc you need to add/allow extra boost in your calcs to allow for "airslip". As a rule of thumb for eg I suggest you use 7psi in the calcs if you really want to finish up with 6psi.

This also applies to worn rootes type blowers where the clearances are not what they were when new.

The Judson and Wray type blowers where the vanes actually "seal/run" on the wall of the bore are quite efficient and you will find the Pulley Ratio calculation formula will be accurate compared with the "real world" figure on your boost guage. This type of blower does tend to run hotter than the non contact ones because of friction.

The engine cooling system must be in A1 condition for a blown motor.

Ignition timing -- rough rule -- retard the spark by 3 degrees (crankshaft) for each unit of compression ratio by which the actual compression ratio (taking into account boost) is raised.

Eg..if you start with a head which is 7:1 and you get an equivalent compression ratio of 9:1 (using the calc/formula) then that is increase of 2 units = 6 degrees retard.In this case if your static timing is 5 before tdc I would change setting to tdc. I don’t suggest you use static timing after tdc. This rule is only a guide -- lots of influences and the best way to sort out your timing and mixture/needle is to spend some money and put it on a commercial dynamometer.

SU or similar carby is best because of its variable choke and ease of tuning,

range of needles etc.

NEVER run on lean mixture -- I have seen an exhaust valve(in molten condition)

completely pulled into the port on the head! Because of a lean, running hot

blown engine.

Hope this helps

Good luck with your project

Harry Pyle